H Testing

H Testing

System and vehicle testing

The laboratory mainly has a fuel cell system testing laboratory (including BOP accessory testing), a fuel cell powertrain testing laboratory, and a fuel cell vehicle testing laboratory, which can carry out testing of the entire development process from fuel cell accessories to fuel cell systems, fuel cell powertrains, and fuel cell vehicle power systems. Equipped with high-precision hydrogen consumption meters and mass spectrometry analyzers, it can achieve analysis of hydrogen consumption and gas composition; The laboratories are all hydrogen related laboratories that meet the standards. They are one of the earliest established fuel cell system and vehicle testing laboratories in China with a wide range of testing projects and rich testing experience.

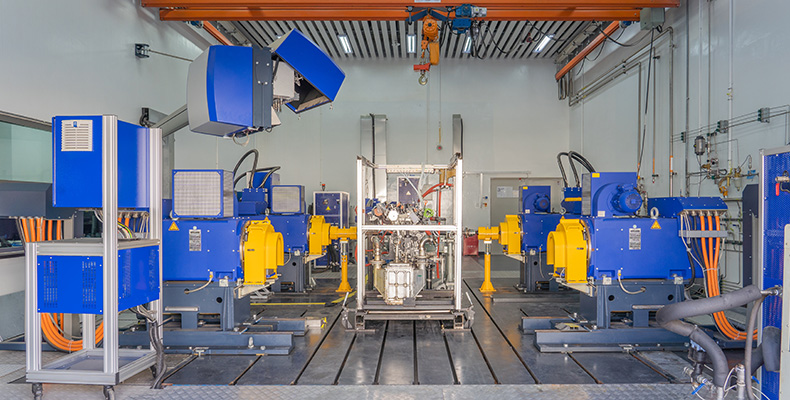

Fuel Cell Powertrain Testing Laboratory

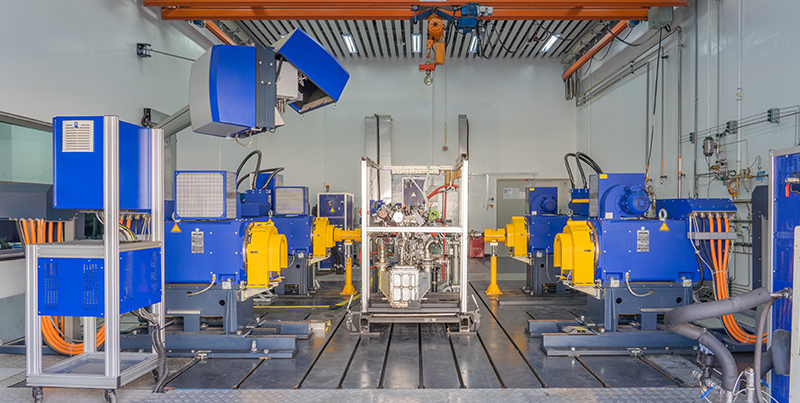

Fuel Cell System Laboratory

Fuel Cell Vehicle Testing Laboratory

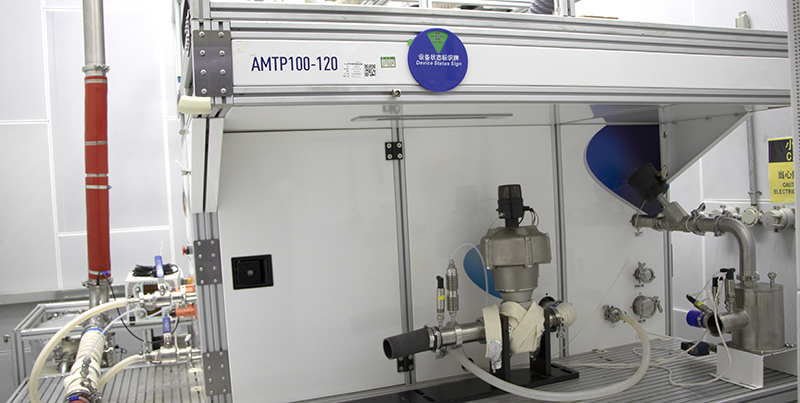

Air Simulation Laboratory

H Introduction

H Introduction

H Follow

H Follow

冀公网安备13060602001687号

冀公网安备13060602001687号