105 MPa high-pressure hydrogen circulation testing equipment

Accumulated 3000 hours of testing experience

The Hydrogen Circulation and Penetration Testing Laboratory is one of the key laboratories for hydrogen energy testing in Test H. It has high-pressure hydrogen circulation testing equipment, with a maximum allowable pressure of 105MPa. The hydrogen filling and discharging rate meets international and domestic standards, and can undertake qualification certification and research and development testing of gas cylinders up to 200L for vehicles.

Hydrogen Circulation and Penetration Testing Laboratory

In terms of professional operation, Dalian Boiler Pressure Testing Research Institute, a certification organization for hydrogen energy testing and gas cylinder products, has reached a long-term strategic cooperation agreement to jointly promote the operation of this testing equipment, providing huge support for the research and development of IV type cylinders in China, and providing safe and efficient high-pressure hydrogen performance and durability testing solutions for gas cylinders and hydrogen related components for manufacturers in the industry.

At present, Test H high-pressure hydrogen circulation testing has served numerous industry-leading clients, accumulating nearly 3000 hours of professional testing experience.

Test H hydrogen energy testing has obtained CNAS laboratory accreditation certificate

Simultaneously promote industry university research cooperation within the industry

Core equipment

1 gas cylinder testing environment warehouse

Three component testing environments仓

Allowable upper pressure limit of 105MPa

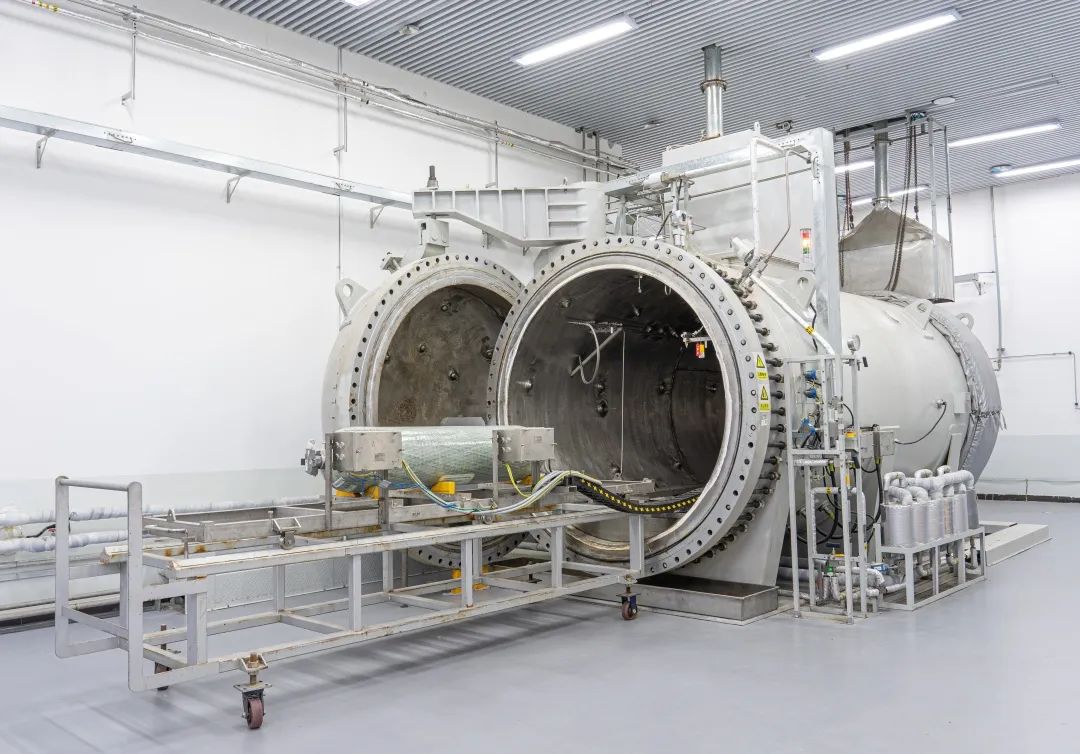

The high-pressure hydrogen circulation testing system consists of a gas cylinder testing environment chamber, three core component testing environment chambers, and a utility section. The testing chamber adopts explosion-proof design and is filled with nitrogen inside to resist physical explosion of the sample. Each testing chamber is independent of each other and can simultaneously test multiple hydrogen related components at different temperatures and pressures.

The temperature control range inside the warehouse is -45 ℃~+85 ℃, and the humidity can reach up to 98%. It can conduct high-pressure hydrogen cycle fatigue tests of 35MPa or 70MPa on hydrogen storage bottles and core components of hydrogen storage systems in low temperature, high temperature, and high humidity environments to evaluate the performance of rapid hydrogen charging and discharging in extreme temperature environments, including hydrogen storage bottles and supporting components.

At the same time, a penetration testing platform can be used to conduct penetration tests on gas cylinders, and analyze the permeability of gas cylinders through gas chromatographs to verify the ability of hydrogen storage systems to perform critical functions throughout the entire vehicle driving process, including product safety and reliability.

Equipment Name: High Pressure Hydrogen Cycle Test System - Gas Cylinder Environment Chamber

Equipment function: Conduct high-pressure hydrogen cycle fatigue test on high-pressure hydrogen storage cylinders

Equipment parameters: Temperature range: -45 to 85 ℃; Gas cylinder capacity: length<3m, diameter<0.5m; humidity: 98%

Applicable products: 35MPa, 70MPa hydrogen storage bottles

Applicable standards:

GBT 35544-2017 Compressed hydrogen gas cylinder with aluminum inner liner and carbon fiber fully wrapped for vehicles

Global technical regulation No. 13 《Global technical regulation on hydrogen and fuel cell vehicles》

ANSI HGV 3.1-2015 《Fuel system components for compressed hydrogen gas powered vehicles》

Test items: Carbon fiber fully wrapped gas cylinder: hydrogen cycle test, performance test, cylinder liner test, room temperature penetration test

Equipment name: High pressure hydrogen circulation test system - component testing environment chamber

Equipment function: Conduct high-pressure hydrogen cycle fatigue test on accessories of high-pressure hydrogen storage cylinder

Equipment parameters: Temperature range: -45 to 85 ℃; Pressure control range: 2Mpa~105Mpa

Applicable products: 35MPa, 70MPa hydrogen storage bottles

Applicable standards:

GTR No.13 《Global technical regulation on hydrogen and fuel cell vehicles》

GBT 35544-2017 Compressed hydrogen gas cylinder with aluminum inner liner and carbon fiber fully wrapped for vehicles

Test items: Pressure reducing valve, pressure reducing valve, TPRD hydrogen circulation test

Cyclic testing under harsh and extreme conditions

Ensure the safety of hydrogen storage

The safety of hydrogen energy in the application process has always been a concern for people. From the perspective of practical engineering applications, as long as reasonable hydrogen energy application equipment and systems are used and operated according to regulations, the safety of hydrogen is guaranteed.

Hydrogen energy equipment belongs to the management category of special equipment and is subject to relevant regulations for special equipment. Before it is officially put into use, its safety and reliability performance need to be evaluated through professional testing methods and quality certification systems. It is necessary to use real high-pressure hydrogen or liquid hydrogen medium for type testing, simulate and assess its performance under extreme conditions and fault tolerance in case of misoperation or failure, and evaluate its performance and service life indicators to ensure batch production quality.

H Introduction

H Introduction

H Follow

H Follow

冀公网安备13060602001687号

冀公网安备13060602001687号